2024-09-15

Stability and resistance to temperature changes for wood swelling or contraction of V-groove engineered wood flooring panel and traditional wood flooring

Compare the stability and resistance to temperature changes for wood swelling or contraction between V-groove engineered wood flooring panel with back-bonded textile (4′ x 8′ large flexible and rollable panel) and traditional wood flooring (joint type piece by piece):

V-groove Engineered Wood Flooring panel with Back-Bonded Textile (4′ x 8′ Large size flexible and Rollable Panel):

Specification sheet of V-groove Engineered Wood Flooring panel

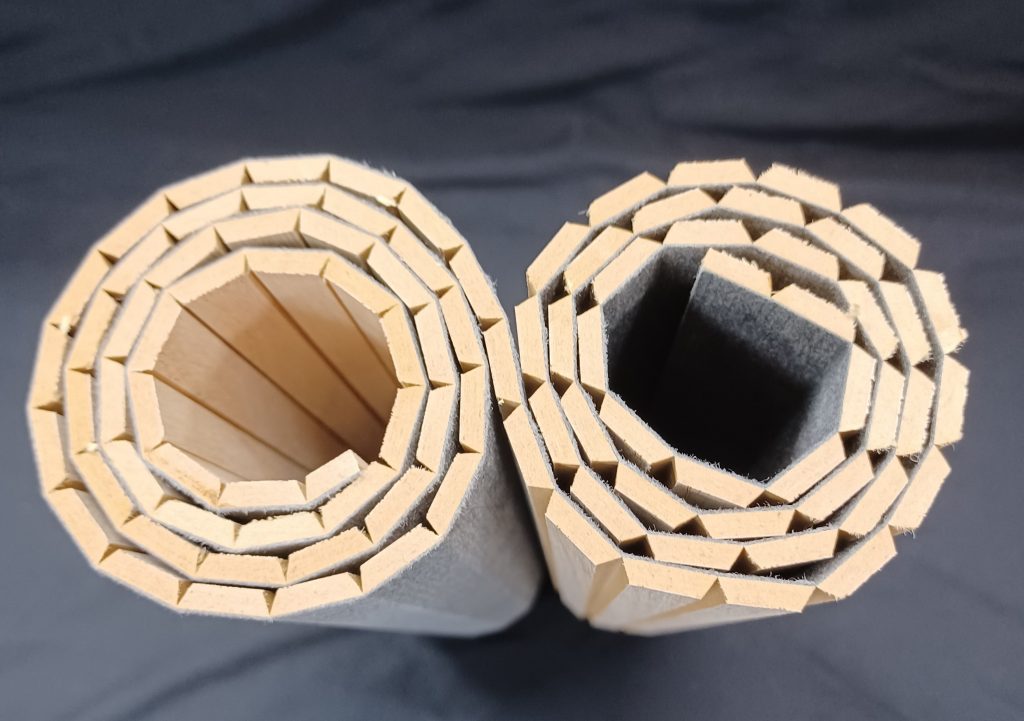

Wood veneer top flexible V-grooved wood slats flooring, wall and ceiling panel boards

Wood kinds: Oak, Maple, Cherry, MDF board

Size: 4 feet X 8 feet (1200 mm x 2400 mm)

Thickness: 3 mm

Flat slat width V-grooved: 13 mm, 43 mm, 67 mm and other widths for special orders

Structure: Top Layer Wood veneer Middle Layer MDF board Bottom Layer ECO resin reinforced non-woven fabric backing

Usages: Stability and resistance to temperature changes for wood swelling or contraction, V-groove engineered wood flooring panel, large size wooden flooring, wood flooring, wooden flooring, flexible engineered wood flooring panel, rollable wood flooring panel, portable wooden flooring, portable and rollable wooden flooring, Interior pole wraps and column covering, wood wall paneling, ceiling, furniture surface covers, old furniture re-new, flooring, wainscoting, pole wrap, column covering, wall paneling boards, kitchen paneling, shiplap wall paneling and backsplash

Origin: Made in Taiwan

Each wood lumber is hand-selected and sanded to ensure you receive the best quality wood panel for slats and sticks fluted flexible wood panel board. The flexible wood panel board can bend at fluted slats or sticks joints to allow for curved applications.

Advantages of V-groove Engineered Wood Flooring panel:

- Stability: The engineered wood panel construction in V-groove engineered wood flooring panel provides excellent stability, reducing the likelihood of warping, cupping, or gaps due to changes in temperature and humidity. The back-bonded textile further enhances its dimensional stability, minimizing expansion and contraction.

- Temperature Resistance: Engineered wood flooring panel, including the V-groove variant, is less prone to significant expansion or contraction due to temperature fluctuations compared to solid wood flooring. The layered construction mitigates the effects of temperature changes.

Traditional Wood Flooring (Joint Type Piece by Piece)

Advantages of Traditional Wood Flooring:

- Stability: Traditional wood flooring, particularly solid wood, is susceptible to expansion or contraction in response to changes in temperature and humidity. Without the structural benefits of engineered wood, solid wood floors might develop gaps or warping during extreme temperature fluctuations.

- Temperature Sensitivity: Solid wood flooring tends to be more sensitive to temperature changes, especially in areas with significant temperature variations. This sensitivity can lead to potential issues with swelling or contraction over time.

Key words: wood swelling, wood contraction, V-groove engineered wood flooring panel, large size wooden flooring, wood flooring, wooden flooring, flexible engineered wood flooring panel, rollable wood flooring panel, portable wooden flooring, portable and rollable wooden flooring, flexible wood panel board