2024-09-18

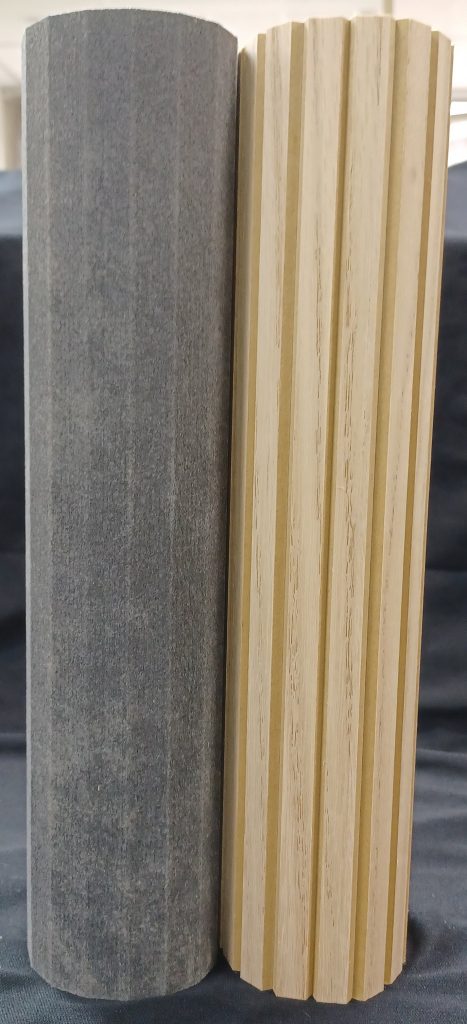

V-groove engineered wood flooring, maintaining the V-grooved lines’ character while ensuring water resistance

Specification sheet of V-grooved slats engineered wood flooring panels

Wood veneer top flexible V-grooved wood slats engineered flooring panel boards

Wood kinds: Oak, Maple, Cherry, MDF board

Size: 4 feet X 8 feet (1200 mm x 2400 mm)

Thickness: 3 mm

Flat slat width V-grooved: 13 mm, 43 mm, 67 mm and other widths for special orders

Structure: Top Layer Wood veneer Middle Layer MDF board Bottom Layer ECO resin reinforced non-woven fabric backing

Usages: V-groove engineered wood flooring, Interior pole wraps and column covering, wood wall paneling, ceiling, furniture surface covers, old furniture re-new, flooring, wainscoting, pole wrap, column covering, wall paneling boards, kitchen paneling, shiplap wall paneling and backsplash

Origin: Made in Taiwan

Each wood lumber is hand-selected and sanded to ensure you receive the best quality wood panel for slats and sticks fluted flexible wood panel board. The flexible wood panel board can bend at fluted slats or sticks joints to allow for curved applications.

For V-grooved slats engineered wood flooring, maintaining the V-grooved lines’ character while ensuring water resistance can be achieved through various methods. Let’s explore some options:

- Water-Resistant Sealant or Resin: One effective method is to fill the V-grooves with a water-resistant sealant or resin. This will protect the grooves from water penetration and help maintain their distinct appearance. The sealant should be applied carefully to ensure it does not affect the overall look of the flooring.

- UV-Cured Oil or Finish: Using a UV-cured oil or finish on the V-grooved lines can add water resistance without compromising the wood’s natural character. This type of finish is durable and can enhance the appearance of the grooves while providing protection against moisture.

- Water-Resistant Paint or Stain: Applying a water-resistant paint or stain to the V-grooves can help preserve their appearance and protect the wood from water damage. Choose a paint or stain that complements the wood species and overall design of the flooring.

- Precision Application: When applying any treatment to the V-grooves, it’s essential to do so with precision to maintain the depth and consistency of the grooves. Avoid excessive application, as it may fill the grooves and diminish their character.

- Regular Maintenance: Keeping the V-grooved lines clean and dry through regular maintenance is essential for preserving their appearance and functionality. Promptly wipe away any spills or moisture that come into contact with the grooves.

Here’s a comparison of the stability and resistance to temperature changes for wood swelling or contraction between V-groove engineered wood flooring with back-bonded textile (4′ x 8′ large rollable panel) and traditional wood flooring (joint type piece by piece):

- Stability:

- V-Groove Engineered Wood Flooring with Back-Bonded Textile: This type of flooring typically offers good stability due to the engineered wood construction. The layers in engineered wood are designed to minimize natural expansion and contraction. The back-bonded textile can also provide added support and reduce the risk of warping or buckling.

- Traditional Wood Flooring (Piece by Piece): Traditional wood flooring, especially when installed as individual pieces with tongue-and-groove joints, can be stable if properly acclimated and installed. However, it is more susceptible to changes in humidity and temperature, which can lead to noticeable expansion or contraction of individual planks.

- Resistance to Temperature Changes and Swelling/Contraction:

- V-Groove Engineered Wood Flooring with Back-Bonded Textile: Engineered wood is generally more resistant to temperature changes and the associated swelling and contraction compared to solid wood. The back-bonded textile can further enhance this resistance by providing additional structural support and preventing moisture infiltration.

- Traditional Wood Flooring (Piece by Piece): Traditional wood flooring, being solid wood, is more prone to swelling in high humidity and contracting in dry conditions. It can exhibit noticeable gaps or warping as a result of temperature and humidity fluctuations. Proper acclimation and maintenance are crucial to minimize these effects.

In summary, V-groove engineered wood flooring with back-bonded textile panels typically offers better stability and resistance to temperature-related swelling or contraction compared to traditional wood flooring installed piece by piece. However, both types of flooring can perform well if installed and maintained properly, with engineered wood having a slight advantage in challenging environmental conditions.

Key words: V-groove engineered wood flooring, wood slats, water resistance,