2024-09-11

Use grooved flexible wood panel board (Tambour board) create a simple up-and-down type Tambour door without a track system

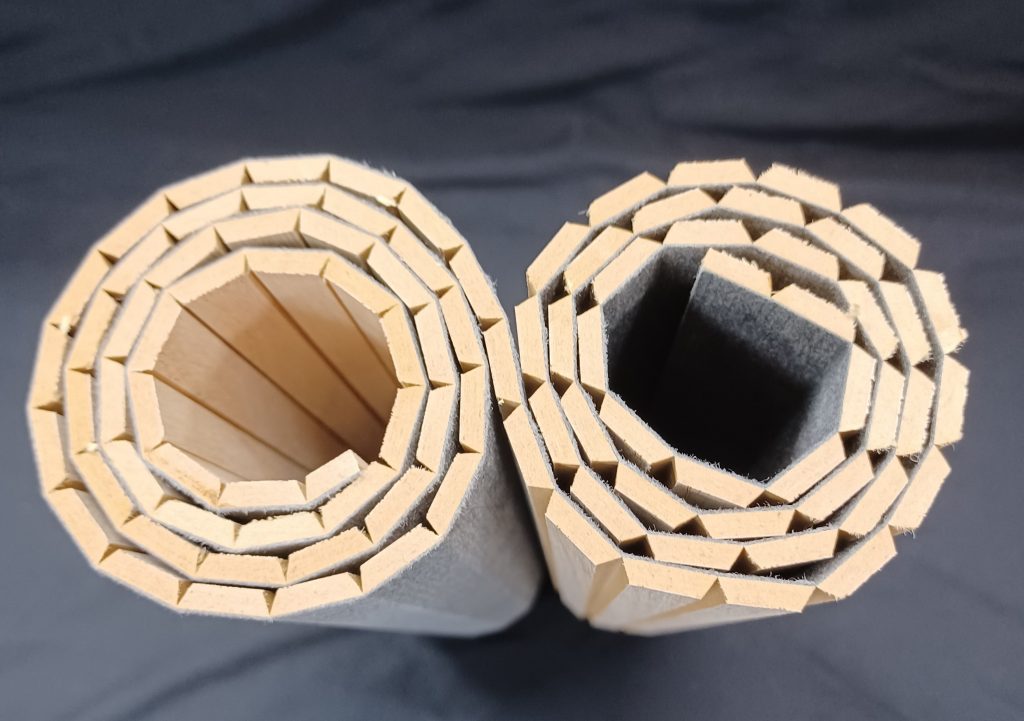

Specification sheet of flexible wood panel board (Tambour board)

Flexible fluted Half-Round Solid wood or MDF Wood sticks wall Panel Board

Wood kinds: Solid Red Oak, MDF board

Size: 4 feet X 8 feet (1200 mm x 2400 mm)

Height: 6 mm

Half round stick: 18 mm width

Backing: ECO resin reinforced non-woven fabric backing

Origin: Made in Taiwan

Wood Veneer top flexible grooved wood slats wall panel board

Wood kinds: Oak, Maple, Cherry, and MDF board

Size: 4 feet X 8 feet (1200 mm x 2400 mm)

Thickness: 3 mm

Flat slat by V-grooved: 13 mm, 43 mm, 67 mm and other widths for special orders

Structure: Top Layer Wood veneer Middle Layer MDF board Bottom Layer ECO resin reinforced non-woven fabric backing or kraft paper

Usages: Tambour door, Tambour board, Tambour boards, V-grooved flexible and rollable wood panel board, flexible and rollable wood panel board, flexible wood panel board, rollable wood panel board, Interior pole wraps and column covering, wood wall paneling, ceiling, furniture surface covers, flooring, wainscoting

Origin: Made in Taiwan

The best Tambour boards, V-grooved Flexible wood panel boards in three layers, top in selected wood veneer, middle MDF board and back with textile support then V-grooved or fluted on the upper two layers for the flexible and rollable character and with slats design will be the best selection for this Tambour door material.

Flexible wood panel boards in three layers, with the top layer made of selected wood veneer, the middle layer made of MDF board, and the back supported with textile, are designed for enhanced flexibility, rollability and durability always the first choose for Tambour door making.

Flexible wood panel board (Tambour board) create a simple up-and-down type Tambour door without a track system

Here’s a basic method to achieve this:

Materials Needed:

V-grooved flexible and rollable wood panel board (Tambour board)

Wood glue or adhesive

Dowels or small wooden rods

Sandpaper

Finish (paint, stain, or varnish)

Steps:

Measure and Cut: Measure the height and width of the opening where you want to install the Tambour door. Use a saw to cut the V-grooved flexible and rollable wood panel board (Tambour board) to the required dimensions. Make sure the cut edges are smooth.

Apply Adhesive: Apply wood glue or adhesive to the backside of the V-grooved flexible and rollable wood panel board (Tambour board). Make sure to spread the adhesive evenly.

Insert Dowels: On the top and bottom edges of the V-grooved flexible and rollable wood panel board (Tambour board), insert dowels or small wooden rods. These dowels will act as guides and allow the Tambour door to move up and down smoothly.

Allow to Dry: Let the adhesive dry according to the manufacturer’s instructions.

Sand and Finish: Sand the edges and surfaces of the Tambour door to achieve a smooth finish. Apply your chosen finish, such as paint, stain, or varnish, according to the manufacturer’s instructions. Allow the finish to dry completely before proceeding.

Installation: Place the Tambour door made of the V-grooved flexible and rollable wood panel board (Tambour board) into the opening, ensuring that the dowels fit into corresponding holes or slots. You can add additional dowels or guides on the sides of the opening to help keep the Tambour door aligned.

Operation: To open or close the Tambour door, gently push or pull the door up or down along the dowels.

Please note that this simple method may not provide the same level of smooth operation and stability as a track system. The Tambour door may require occasional adjustment to ensure proper alignment and movement. Additionally, the absence of a track system means that the door might not have as tight a seal when closed, potentially affecting its ability to provide insulation or privacy.

Opening and closing a Tambour door involves a unique rolling action that allows the door to smoothly slide up and down along a set of guides or dowels.

Here’s a detailed description of how to operate a Tambour door made of the V-grooved flexible and rollable wood panel board (Tambour board)

Opening the Tambour Door:

Starting Position: The Tambour door is initially in the closed position, covering the opening. It appears as a flat panel.

Gently Pushing: To open the Tambour door made of the V-grooved flexible and rollable wood panel board (Tambour board), gently apply pressure to the bottom of the door with your hand. This pressure will initiate the rolling action.

Rolling Action: As you push upwards, the Tambour door will start to roll up along the guides or dowels that are located on the sides of the opening. The V-grooved flexible and rollable wood panel board (Tambour board) will fold upon each other as they roll.

Continued Pushing: Continue pushing the door upwards. The door will gradually and smoothly roll up, revealing the interior behind it. You can control the speed at which the door rolls up.

Fully Opened Position: When the Tambour door is fully open, it will be completely rolled up and hidden within the upper portion of the opening. The interior space is now fully accessible.

Closing the Tambour Door:

Starting Position: The Tambour door is fully open and rolled up at the top of the opening.

Gently Pulling: To close the Tambour door, gently apply pressure to the top of the door with your hand. This will initiate the rolling action in the opposite direction.

Rolling Action: As you pull downwards, the Tambour door will start to unroll and roll down along the guides or dowels. The flexible wood panels will unfold and lay flat as they roll down.

Continued Pulling: Continue pulling the door downwards. The door will smoothly unroll and cover the opening.

Fully Closed Position: When the Tambour door is fully closed, it will be a flat panel that covers the entire opening, providing privacy and concealment.

Key Points to Remember

The rolling action of the Tambour door made of the V-grooved flexible and rollable wood panel board (Tambour board) allows for a space-saving and elegant opening and closing mechanism.

The flexibility of the made of the V-grooved flexible and rollable wood panel board (Tambour board) enables them to fold and unfold smoothly during the rolling process.

You can partially roll the Tambour door to control ventilation and visibility, or fully roll it up for complete access.

The absence of a track system means that the Tambour door’s movement relies on the guides or dowels on the sides of the opening.

For this Tambour door, what the thickness of the made of the V-grooved flexible and rollable wood panel board (Tambour board) used?

The thickness of the made of the V-grooved flexible and rollable wood panel board (Tambour board) for making a Tambour door can vary depending on the specific design, application, and aesthetic preferences. However, a common thickness range for Tambour boards used in doors is typically between 3 mm to 9 mm).

Here are some considerations to help you determine the appropriate thickness for your made of the V-grooved flexible and rollable wood panel board (Tambour board).

Function and Durability If the Tambour door will be frequently operated or subjected to regular use, opting for a thicker Tambour board can enhance its durability and longevity.

Flexibility Thinner V-grooved flexible and rollable wood panel board (Tambour board) may offer greater flexibility, allowing for easier rolling and unrolling. However, thicker V-grooved flexible and rollable wood panel board (Tambour board) might be more rigid and provide a sturdier structure.

Appearance Consider the overall aesthetic and design of your Tambour door. Thinner Tambour boards might offer a sleek and modern look, while thicker Tambour boards can create a more substantial and traditional appearance.

Weight Thicker Tambour boards will generally be heavier. Ensure that the weight of the chosen thickness is suitable for the hardware and installation method you intend to use.

Compatibility Check the compatibility of your chosen thickness with any hardware or track systems you plan to incorporate.

Wood Type Different wood species have varying densities and characteristics. Some woods might be better suited for thinner Tambour boards, while others may work well with thicker boards.

Ultimately, the choice of Tambour board thickness should be based on your specific requirements, intended use, and desired visual outcome. It’s a good idea to consult with a professional or experienced woodworker to ensure you choose the right thickness for your Tambour door project.

Key words: Tambour door, Tambour board, Tambour boards, V-grooved flexible and rollable wood panel board, flexible and rollable wood panel board, flexible wood panel board, rollable wood panel board