2024-09-15

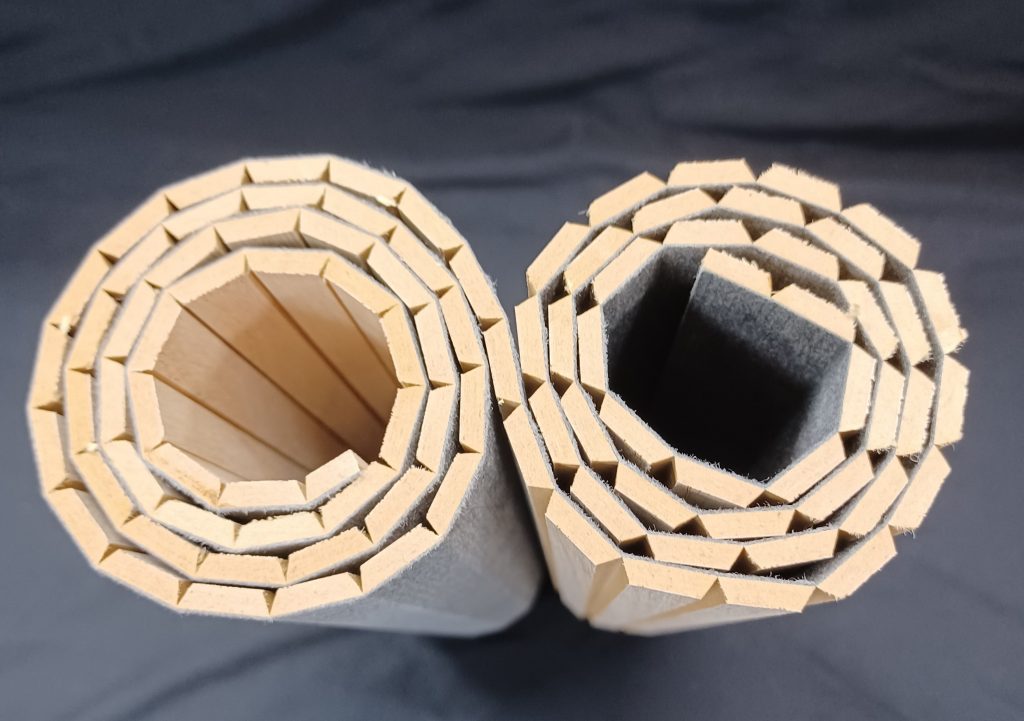

V-groove engineered wood flooring with back-bonded textile (4′ x 8′ large size rollable panel) and traditional wood flooring (joint type piece by piece) for DIY user consideration

Compare V-groove engineered wood flooring with back-bonded textile (4′ x 8′ large size rollable panel) and traditional wood flooring (joint type piece by piece) for DIY user consideration:

1. V-groove Engineered Wood Flooring with Back-Bonded Textile (4′ x 8′ Large size flexible and Rollable Panel type):

Specification sheet of V-groove Engineered Wood Flooring

Wood veneer top flexible V-grooved wood slats flooring, wall and ceiling panel boards

Wood kinds: Oak, Maple, Cherry, MDF board

Size: 4 feet X 8 feet (1200 mm x 2400 mm)

Thickness: 3 mm

Flat slat width V-grooved: 13 mm, 43 mm, 67 mm and other widths for special orders

Structure: Top Layer Wood veneer Middle Layer MDF board Bottom Layer ECO resin reinforced non-woven fabric backing

Usages: Interior pole wraps and column covering, wood wall paneling, ceiling, furniture surface covers, old furniture re-new, flooring, wainscoting, pole wrap, column covering, wall paneling boards, kitchen paneling, shiplap wall paneling and backsplash

Origin: Made in Taiwan

Each wood lumber is hand-selected and sanded to ensure you receive the best quality wood panel for slats and sticks fluted flexible wood panel board. The flexible wood panel board can bend at fluted slats or sticks joints to allow for curved applications.

Advantages of V-groove Engineered Wood Flooring:

- Large flexible and Rollable engineered wood flooring Panels: The V-groove engineered wood flooring panel with back-bonded textile comes in large 4′ x 8′ size flexible and rollable panels, making it easier and quicker to cover larger floor areas. This saves time and effort during installation compared to traditional wood flooring that requires assembling individual pieces.

- Flexibility: The flexible and rollable nature of the large size V-grooved engineered wood flooring panel allows for greater flexibility during installation. It can be easily unrolled and adjusted to fit the floor space accurately, resulting in a more efficient DIY process.

- Simple Glue Application: This type of engineered wood flooring panel often requires only a simple glue application to adhere it to the sub floor, making the DIY installation process straightforward and accessible to users with basic skills.

- Seamless Appearance: The large size engineered wood flooring panel design minimizes the number of seams on the floor surface, creating a more seamless and continuous look. This contributes to a visually appealing and uniform flooring design.

2. Traditional Wood Flooring (Joint Type Piece by Piece):

Advantages of Traditional Wood Flooring :

- Authentic Appearance: Traditional wood flooring offers an authentic look of solid wood, showcasing the natural beauty and character of the wood species used. It appeals to those seeking a classic and timeless aesthetic.

- Customization: With individual pieces, users have more flexibility to create unique patterns and designs, such as herringbone or parquet, according to their preferences and creativity.

- Repair and Replacement: In case of damage to a specific area, it is easier to replace individual pieces, making repairs more manageable and cost-effective.

- Traditional Craftsmanship: For some DIY enthusiasts or homeowners, the process of laying down individual wood pieces offers a sense of craftsmanship and satisfaction.

Key words: DIY process. engineered wood flooring panel, large size flooring panel, V-groove engineered wood flooring panel, large size flexible and rollable flooring panel, wood flooring, DIY installation